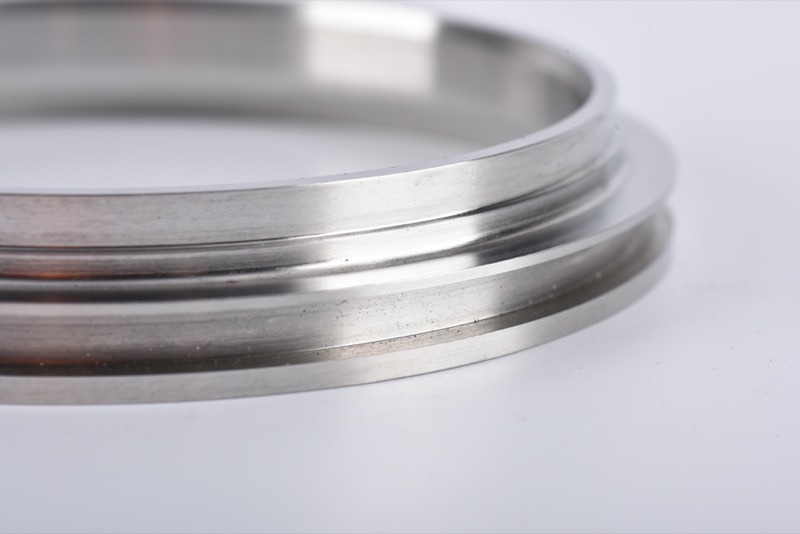

Description

| Dimension (mm) | ||

| OD | ID | H |

| 63.398 | 46.507 | 9.474 |

| 69.774 | 46.507 | 9.474 |

| 69.774 | 53.010 | 9.474 |

| 85.649 | 65.583 | 9.474 |

| 95.148 | 65.583 | 14.224 |

| 99.898 | 79.985 | 9.474 |

| 111.050 | 79.934 | 14.224 |

| 130.070 | 105.283 | 9.474 |

| 130.070 | 105.283 | 14.224 |

| 139.600 | 105.283 | 17.424 |

| 161.900 | 130.175 | 17.424 |

| 184.070 | 157.099 | 14.224 |

| 184.070 | 162.433 | 14.224 |

| 222.200 | 162.433 | 17.399 |

| 222.250 | 180.975 | 17.272 |

| 235.080 | 180.975 | 22.225 |

TMetal is committed to help customers withstand high-temperature, wear and corrosive conditions by ensuring finished products an enhancing operation life and a reducing downtime.

TMetal’s customized options allow customers to get the seal ring that can fit any type of pump and valves.

Each of our finished seal rings must pass through our quality assurance team for a full inspection before delivery.

Advantages of Powder Metallurgy

With powder metallurgy you greatly reduce post-production processes such as metal removal procedures.This does not only reduce yield losses and total costs, but also lowers turnaround time in manufacturing.